market leading Purge and Pressurisation safety device

Purge System

PPI Engineering’s market leading Purge and Pressurisation safety device ensures the safe operation of electrical machines and enclosures within Zone 1/21 and 2/22 hazardous areas. The unique attributes of this system provide numerous advantages over its competitors.

Concept – Refer to brochure for more details

PP1214 is designed in accordance with IEC 60079-2:2014 Ed 6/ EN 60079-2:2007, ensuring a pressurised and leakage compensated enclosure. This creates a non-hazardous atmosphere inside the enclosure by keeping a positive differential pressure between the pressurised enclosure and atmospheric pressure to ensure that no potentially explosive gases enter the electrical equipment.

This type of protection consists of two main stages:

Purge Cycle:

Activated when the electrical machine is OFF prior to being switched ON. Clean air/inert gas is blown through the machine and monitored to ensure compliance with IEC 60079-2:2014 Ed 6/ EN 60079-2:2014.

Leakage Compensation and Pressurisation Cycle:

Once purge cycle is satisfactory the machine is considered non-hazardous and ready to be switched ON. A positive differential pressure to atmospheric has to be maintained. This is achieved by compensating for any air/inert gas leakages that the machine might have.

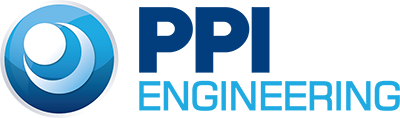

Inlet Unit

Outlet Unit

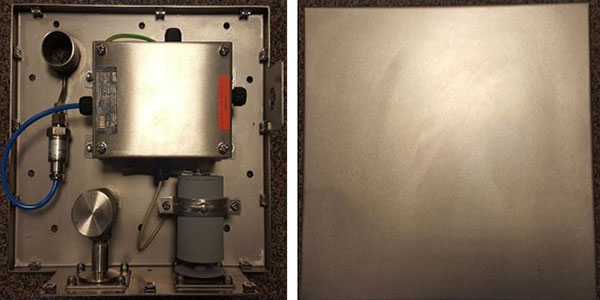

Micro Controller

System Advantages

- Minimum supply pressure of 3 barg

- Fully automatic electronically controlled system, reducing commissioning time (does not require outlet valve orifice plate changing to achieve correct flow rate)

- No pneumatic connections between inlet and outlet unit, reducing installation time

- Automatically compensates varying air leakages in machine, eliminating the need for manual valve leakage adjustment

- Automatic machine leakage compensation display – essential information for machine maintenance

- LCD information display

- Mechanically interchangeable with expo systems

- Up to 4250ls/min [standard litres per minute] automatic leakage compensation already built in, i.e. no additional “BOOST”equipment needed to increase leakage compensation

- Local or remote control/monitoring

- No pneumatic logics used, therefore reducing the possibility of faults created by leakages or blockages

- Risk of failure minimised due to simplified layout – fewer components needed

| MODEL | CONTROL | LEAKAGE COMPENSATION |

|---|---|---|

| PPI214.1.1 | Remote | Manual Ball Valve |

| PPI214.2.1 | Local | Manual Ball Valve |

| PPI214.3.1 | Remote | Automatic Electrical Solenoid Valve |

| PPI214.4.1 | Local | Automatic Electrical Solenoid Valve |

| PPI214.PV.3.1 | Remote | Pre-Start Ventilation |

| PPI214.PV.4.1 | Local | Pre-Start Ventilation |